Best Greases for Private Labeling in Africa, Asia & CIS

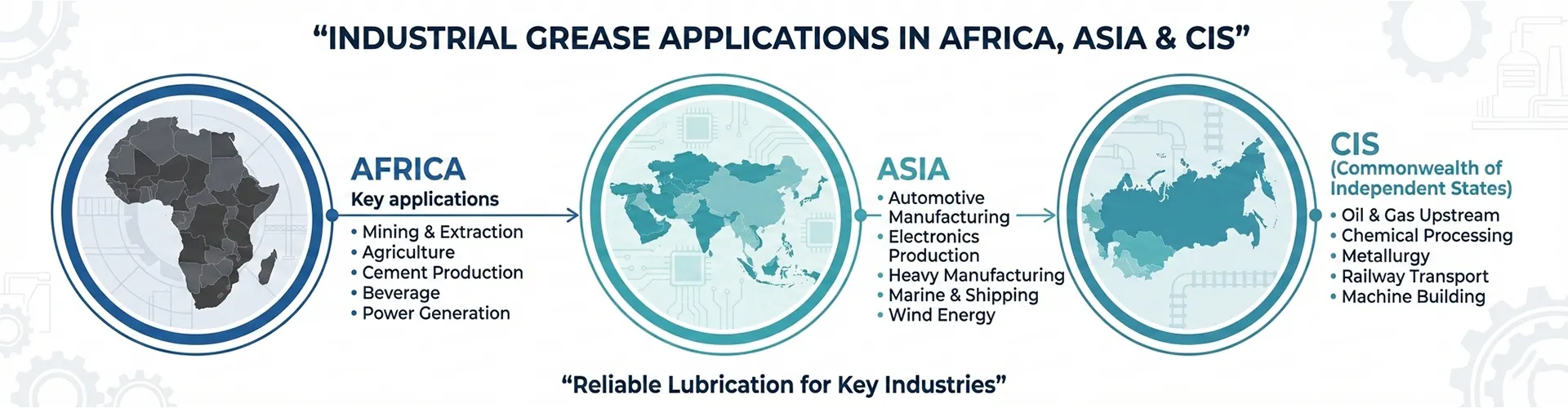

Launching a private label grease line in regions like Africa, Asia, and the CIS countries is one of the smartest business moves nowadays. These markets are rapidly growing, driven by expanding construction, rising vehicle ownership, industrial development, and a continuous improvement for reliable lubrication solutions.

But the real challenges are: not all greases do well in hot climates, dusty environments, or heavy-load applications, conditions very common across these regions. So, if you’re planning to enter the private label grease business, selecting the right formulations is the key to long-term success.

This guide will help you to go through the best greases for private label branding, specifically manufactured for Africa, Asia, and CIS. You’ll see what performs well, what your customer preference is, and which products new brands should start with. You can learn more about start your own grease brand.

1. Why Private Label Grease Demand Is Increasing in Africa, Asia & CIS

These countries have three common factors:

High temperatures

Many regions experience extreme heat (35°C–50°C), which can damage standard greases to melt, oxidize, or break down faster.

Heavy-duty usage

Vehicles, construction equipment, and industrial machines work under tough condition heat, dust, moisture, and load.

Demand for cost-effective but durable products

Customers prefer reliable grease that delivers performance without high pricing.

This is exactly why private label branding is growing businesses can offer tailored, climate-fit products without having a factory. You can Explore ideal packaging for private label grease products.

2. What Makes a Grease Appropriate for These Markets?

Before selecting your private label grease types, understand what are the most valued features in Africa, Asia, and CIS:

High-temperature resistance

Greases should maintain structure above 180°C–200°C.

Strong water resistance

Perfect for wet weather, humid ports, or coastal industries.

Anti-wear & load-carrying capability

Essential for trucks, tractors, and construction equipment.

Oxidation stability

Heat and dust accelerate oxidation; customers want long-lasting grease.

Affordable formulation

Brands must maintain a balance between performance and price for highly competitive markets.

3. Best Greases for Private Labeling

Let’s examine the most suitable grease types for private label branding in Africa, Asia, and CIS.

1. Lithium EP2 Grease

The primary uses are automotive, industrial, and heavy equipment. Lithium EP2 Grease works well in handling high temperatures, resists water and contamination, is extremely versatile, and is the most popular globally. It is by far the best grease for private label brands starting in these regions because the demand is steady, consistent, and universal.

Many new brands choose formulations similar to Rexol Lithium EP2 Grease because of its balanced price-to-performance ratio.

2. Lithium Complex Grease

The primary uses are extreme heat and heavy load machinery. Lithium complex grease is preferred for higher dropping point, ability to handle 250°C+, long-lasting under stress conditions, and suitability for African and Middle Eastern climates.

3. High-Temperature Grease

The primary uses are bearings, wheel hubs, and high-speed operations. High-temperature greases are essential for stability at very high temperatures, perform well under fast rotation, and reduce the chance of grease leakage.

4. Multipurpose NLGI 2 Grease

The primary uses are workshops, agricultural equipment, and auto repairs. Multipurpose NLGI 2 Grease works well for general lubrication needs and is easy to sell in high volume because of its affordable prices.

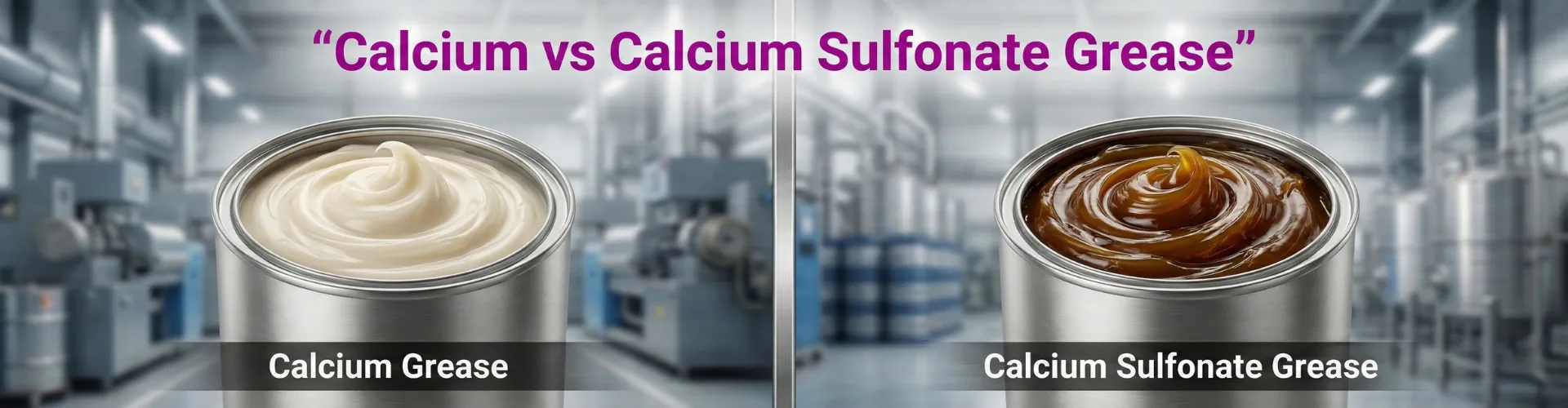

5. Calcium and Calcium Sulfonate Greases

Calcium Grease are very cost-friendly, good for general-purpose lubrication, and ideal for high-volume African markets. Calcium Sulfonate Grease handles moisture extremely well and is used in marine, fishing, coastal operations.

6. Moly Grease with Molybdenum Disulfide

Moly Grease with Molybdenum Disulfide works best for heavy machinery, mining, and earthmoving equipment. It used for excellent load-carrying capacity. It reduces wear under shock loads.

4. Choosing the Best Grease for Your Private Label Brand

If you’re launching your grease brand for the first time, understanding grease types and applications, here’s the recommended starter lineup:

- Lithium EP2 Grease used for mass market leaders.

- Multipurpose NLGI2 Grease used for high sales turnover

- High-Temperature Grease used for hot climates

- Lithium Complex Grease used for premium industrial clients

5. Packaging Types That Work Best in These Regions

Africa

- 500g–1kg tubs

- 180kg drums

- 400g cartridges

Asia

- 500g cups

- 400g cartridges

- 15kg pails

CIS Countries

- 400g cartridges (very high demand)

- 50kg and 180kg drums

- Industrial pails

6. Why Does Environment Matter When Selecting Grease?

Temperatures in many African and Asian countries regularly reach 40°C–50°C, and that affects the grease stability. On the other hand, CIS countries have -20°C to 40°C, which requires temperature-stable greases.

For hot climates (African and Asian):

- Lithium Complex Grease

- High-Temperature Grease

- EP Greases

For mixed climates (CIS):

- Multipurpose Grease

- EP Grease

- Synthetic or semi-synthetic greases

7. Working with the Right Private Label Partner

A trustworthy private label manufacturer will help you:

- Select the ideal grease types

- Match your climate requirements

- Design premium packaging

- Develop MSDS and TDS documents

- Maintain consistent batch quality

You can explore our private label services and pricing model here:

👉 Private Label Grease Pricing Model

👉 Private Label Manufacturing Page

Final Thoughts

If you want to build a grease brand that performs well across Africa, Asia, and CIS, you must select formulations that stand up to heat, dust, moisture, and heavy workload.

The best greases for private label branding in these regions are:

- Lithium EP2 Grease

- Multipurpose Grease

- High-Temperature Grease

- Lithium Complex Grease

- Moly & Calcium Sulfonate Greases

If you want to develop your own grease brand, contact Rexol for private label grease production. Also if you want guidance by region, read our private label grease in India and Private Label Grease in Pakistan guides.