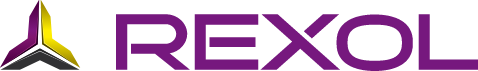

Calcium vs Calcium Sulfonate Grease – Key Differences & Applications

The most common question while working with the industrial lubrication is “What is the difference between calcium vs calcium sulfonate grease?”

Both are known for their water resistance properties. Both are used in heavy-duty environments, but, in real-world applications, the calcium vs calcium sulfonate grease comparison is not small.

This guide breaks down the differences in a practical way. It explains how these greases behave, where they work best, and how to choose the right one.

Understanding the Basics: What Is Calcium Grease?

The oldest and most traditional grease being used today is calcium grease. Calcium grease, also called calcium soap grease, is mainly used for one reason, and that is its excellent water resistance.

Key characteristics of calcium grease

- Very good resistance to water washout

- Soft and smooth texture

- Good corrosion resistance

- Cost-effective formulation

The only drawback of calcium grease is that it cannot withstand high temperatures. As soon as the temperature rises, it starts to soften and lose its structure because of its low dropping point. This makes it difficult to stay in place and protect the equipment.

Typical calcium grease applications

- Agricultural equipment

- Marine deck equipment

- Water pumps

- Low-speed bearings

- Applications exposed to frequent water splash

In short, calcium grease works well where water is the enemy, but heat is not a major concern.

What Is Calcium Sulfonate Grease (and why it’s different)

Calcium sulfonate grease is not just an upgraded calcium grease—it’s a different technology altogether.

Calcium sulfonate grease uses a different chemically reinforced structure that contains calcium carbonate particles and sulfonate molecules. This structure and extra calcium give the strength to this grease and provide EP properties.

This is why calcium sulfonate grease is now popular in many industries.

Core features of calcium sulfonate grease are:

- Excellent water resistance (often better than calcium grease)

- Very high load-carrying capacity

- Strong natural EP performance

- High dropping point

- Outstanding corrosion protection

- Very stable structure under mechanical stress

These properties make calcium sulfonate grease a great replacement for lithium complex or aluminum complex grease.

Calcium vs Calcium Sulfonate Grease – The Real Differences

Here’s where the comparison becomes practical.

1. Temperature resistance

- Calcium grease: It performs well at limited or low-to-moderate temperatures

- Calcium sulfonate grease: It performs well at high operating temperatures

If temperature is involved, calcium sulfonate is the clear winner.

2. Load-carrying capability

- Calcium grease: It can handle light to moderate loads.

- Calcium sulfonate grease: Excellent load-carrying capacity, even under shock loads

This is one of the biggest and main differences between calcium grease and calcium sulfonate grease.

3. Water resistance

- Both perform well, but when it comes to continuous water exposure and high temperatures, calcium sulfonate often leads

4. Corrosion protection

Widely known for their exceptional corrosion resistance property, calcium sulfonate greases become an ideal choice for marine and coastal environments.

5. Mechanical stability

Calcium grease loses its structure under shear because of its low dropping point. On the other hand, calcium sulfonate grease maintains its structure even in heavily loaded bearings.

Where Calcium Grease Still Makes Sense

Despite its limitations, calcium grease still has a place where the equipment is operating at low speed, in environments where exposure to water is constant but heat is low, and in applications that are cost-sensitive and premium performance is not required.

The most common calcium grease applications are:

- Wheel bearings

- Agricultural equipment

- Chassis lubrication

- Low-temperature machinery

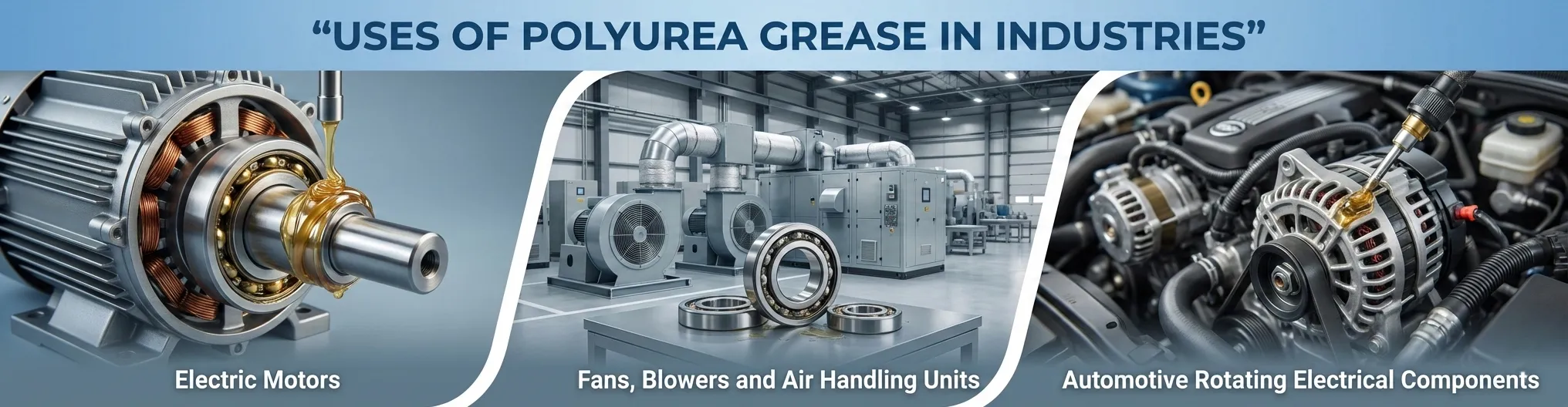

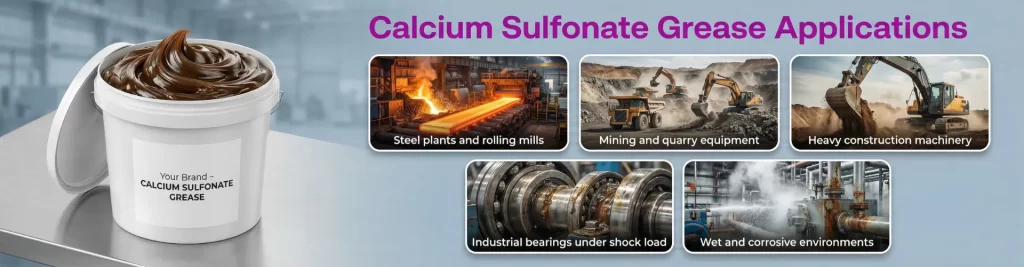

Calcium Sulfonate Complex Grease Applications

This is where calcium sulfonate truly stands out.

Common calcium sulfonate complex grease applications

- Steel plants and rolling mills

- Mining and quarry equipment

- Marine and offshore applications

- Heavy construction machinery

- Industrial bearings under shock load

- Wet and corrosive environments

In many industries, calcium sulfonate grease is chosen not just for performance but for reliability under extreme conditions.

Is Calcium Sulfonate Grease Always Better?

Not necessarily.

Calcium grease can be a smarter choice where your application doesn’t need high temperature or extreme load resistance. Calcium sulfonate grease comes with a premium performance at a higher cost.

The main factor is matching grease capability to actual operating conditions, not just choosing the most advanced option.

Choosing Between Calcium Grease and Calcium Sulfonate Grease

Ask these practical questions:

- Is the application exposed to high temperatures?

- Are loads heavy or subject to shock?

- Is water exposure constant or occasional?

- How critical is equipment uptime?

- Is cost or performance the main priority?

This is where experience matters.

Rexol doesn’t treat calcium grease and calcium sulfonate grease as interchangeable products. Each grease formulation is customized based on the real application needs and not just the standard values.

Rexol Calcium Grease

Rexol’s calcium grease is designed for the applications where water is the enemy. It is cost-effective and can be used in industrial and marine applications.

Rexol Calcium Sulfonate Grease

Rexol’s calcium sulfonate grease is designed for high-load applications where the temperature rises and often needs corrosion resistance properties.

These greases are also available for private label under your own brand because calcium and calcium sulfonate greases are widely used across industries, which makes them ideal for private labeling because of:

- Strong demand

- Easy to position in industrial and marine markets

- Clear performance differentiation

- Suitable for multiple packaging formats

Distributors can start with the basic calcium grease and can expand to calcium sulfonate grease later according to the market needs.

👉 Learn more on our Private Label Grease Manufacturing page.

Final Thoughts

The difference between calcium vs calcium sulfonate grease is not just based on the technical points—it’s based on the practical operating conditions of the equipment.

Calcium grease remains a reliable, water-resistant, and economical option for basic needs.

Calcium sulfonate grease on the other hand steps in when heat, load, and corrosion push equipment to its limits.

It’s not just about the current trends, its about understanding what the application operating conditions are and choosing the right grease accordingly.

With an experienced private label grease manufacturing partner, you get the right formulations to confidently serve both ends of the market.