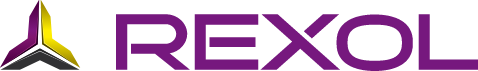

Where to Use Polyurea Grease? A Complete Industry Guide

Polyurea grease has been a popular name in modern lubrication. It is not as widely discussed as lithium or calcium grease, but polyurea is a quiet performer, especially for the applications where heat, speed, and long service life are critical.

This guide is written to help clearly understand polyurea grease applications, where it performs best, and when it may (or may not) be the right choice.

What makes Polyurea Grease different?

Greases are majorly made of 3 major components: base oil, thickener, and additives. Thickener acts like a sponge, which holds the oil and then slowly releases it during operation. Polyurea grease uses a urea-based thickener and not soap-based like lithium or calcium grease. Polyurea grease is designed to give enhanced lubrication in the system where an extended service life is required.

Other polyurea grease uses are:

- Excellent rust protection

- Strong heat resistance

- Very good mechanical stability

- Long service life in sealed or semi-sealed bearings

- Clean running behavior with minimal deposit formation

These properties make polyurea grease a great choice for applications where frequent relubrication is not possible. Check our article about select the right grease—grease type fundamentals.

Polyurea grease is mainly used in:

- Electric Motors

- Fans, Blowers and Air Handling Units

- Sealed or semi-sealed bearings

- Automotive and Rotating electrical components

- Industrial manufacturing plants

Why Polyurea Grease Is Commonly Used in Electric Motors

Polyurea grease is commonly used in electric motor bearings to fulfill the extreme lubrication need of the application. It usually requires a grease that can handle heat, speed and long operating cycles

Electric motors often operate under:

- Continuous or near-continuous duty

- High temperatures

- High rotational speeds

- Limited relubrication access

Polyurea grease for electric motors is the best choice because of its anti-rust properties even at high temperatures and its ability to maintain its structure. This helps reduce grease hardening, oil separation, and premature bearing failure.

Different motor-related applications

- Industrial electric motors

- HVAC motor bearings

- Cooling tower fan motors

- Pump motors

- Conveyor drive motors

For different application requirements like higher-temperature or extended life-requirements, try our different Polyurea greases and improve your application’s life. Find the best greases for private label brands.

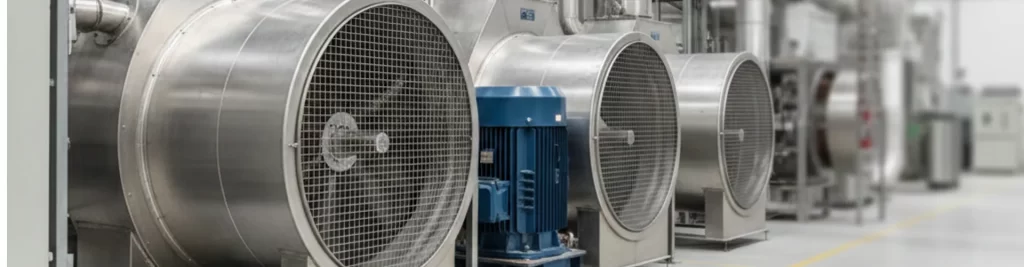

Polyurea Grease in Fans, Blowers, and Air Handling Units

Another area where polyurea grease is widely used is in fans and blowers because they work continuously at high speed. Polyurea grease is a great choice for the conditions where high speed requires grease stability.

Common applications

- Industrial ventilation fans

- Exhaust and process air blowers

- Cooling fans in manufacturing plants

- HVAC air handling unit (AHU) bearings

Polyurea grease stands out for its long relubrication intervals and its clean performance. These properties reduce the grease breakdown and improve the life of the bearing in high-temperature environments.

Check out our NLGI 1.5 Polyurea grease for the systems that require centralized lubrication or specific bearing designs.

Sealed-for-Life Bearings and Long Service Intervals

Nowadays modern machines are designed with sealed or semi-sealed bearings. This reduces the access for relubrication. In this case, polyurea grease plays an important role and selecting the correct grease becomes part of the equipment’s reliability strategy.

Polyurea grease is frequently chosen for:

- “Lubed-for-life” electric motor bearings

- Bearings in enclosed housings

- Equipment with limited maintenance access

Its anti-rust property and mechanical breakdown allows it to remain effective over extended periods, reducing the risk of grease hardening or excessive oil separation.

Automotive and Rotating Electrical Components

Polyurea grease also support applications where rotating electrical components are involved.

Typical uses

- Alternator bearings

- Starter motor bearings

- Certain accessory bearings (depending on OEM specification)

In these applications, thermal stability and clean performance are the main requirements. The performance of the bearing is hampered by inconsistent lubrication and the formation of deposits. Polyurea grease helps prevent the formation and gives a consistent lubrication for a smooth bearing performance.

Polyurea Grease in Industrial Manufacturing Plants

Manufacturing equipment requires attention, and its downtime can be far costlier than the lubricant itself. The goal is to have reliable products with minimal intervention.

Common plant applications are:

- Packaging line bearings

- Conveyor rollers (moderate load, high speed)

- Light-duty industrial bearings

- Electric motor-driven equipment

Polyurea grease helps in supporting extended maintenance intervals, stays stable and runs clean.

Choosing the Right Polyurea Grease Grade

Selecting the correct NLGI grade and base oil type is just as important as choosing polyurea itself.

NLGI 2 Polyurea Grease

The most commonly used grade for its power of extended melt time and is suitable for most electric motor and fan applications.

Check out Rexol NLGI 2 Polyurea grease

NLGI 1.5 Polyurea Grease

Slightly softer than NLGI 2, this grade is useful where improved flow or pumpability is required.

Please check Rexol NLGI 1.5 mineral oil-based Polyurea grease

Synthetic Polyurea Grease

Synthetic polyurea grease is typically chosen for:

- Higher operating temperatures

- Wider temperature ranges

- Extended service life expectations

Check out Rexol Synthetic Polyurea grease range

Where Polyurea Grease May Not Be the Best Choice

Regardless of its advantages, polyurea grease is not a solution to every problem. Here are some regions where Polyurea grease may not be the best choice

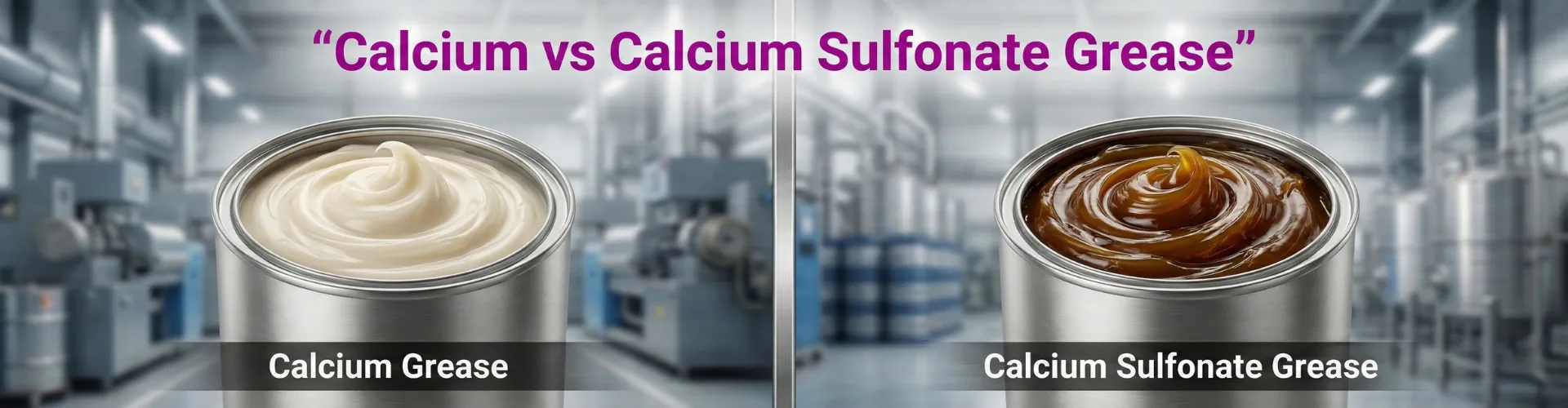

Grease compatibility

One of the most common issues seen is the mixing of the thickener type, such as lithium or calcium, with polyurea grease, which can lead to incompatibility. This can further lead to softening, structural breakdown, or oil leakage.

Heavy shock-load applications

Polyurea grease will not be suitable for pins, bushings, or heavily loaded slow-moving components unless it is specifically formulated for such conditions.

Severe water washout

Despite its property to work well in moist environments, polyurea grease may not perform well in applications with continuous water exposure.

Relubrication Tips for Best Performance

If applied incorrectly, even the high-performance grease can fail. Always make sure to:

- Avoid over-greasing electric motor bearings—this can increase heat and cause seal damage.

- Follow OEM relubrication quantities and intervals.

- Monitor bearing temperature and vibration when extending intervals.

- Store grease properly to prevent contamination before use.

Final Thoughts: When Polyurea Grease Makes Sense

Modern equipment demands consistent performance and reduced maintenance effort. Polyurea grease plays an important role here and understanding polyurea grease applications, selecting the correct grade, and applying it correctly makes a whole lot of difference.

Its stability in performance and clean-running nature makes it an ideal choice for applications that involve high-speed bearings, elevated temperatures, or long service intervals. Rexol makes this grease available for private label production under your own brand name. For more details, please contact our technical team or check out our private label grease page.